Eaton and BAE Systems have tested an integrated electric drive for mid- and heavy-duty trucks.

Eaton and BAE Systems have tested an integrated electric drive for mid- and heavy-duty trucks. (Photo: BAE Systems)

Eaton Corporation has a massive portfolio of products covering virtually any power application, ranging from energy storage systems through to backup power and vehicle drivetrains.

Dr. Mihai Dorobantu, Eaton Corporation.

“As a company, Eaton believes that governments should outline specific environmental targets.” Dr. Mihai Dorobantu, Eaton Corporation. (Photo: Eaton)

In a recent interview with PPI, Dr. Mihai Dorobantu, director of Advanced Technology at Eaton, explained that virtually all the programs operated by his division over the past 15 years have involved ways to reduce engine emissions. This has primarily focused on CO2 and NOx emissions, with the intent of reducing the impact of these greenhouse gases (GHG) on climate and air quality.

“It’s not by chance that we have suddenly appeared with these emissions solutions,” said Dorobantu. “If what you put in at the front end of the process are ways to reduce emissions, 15 years later it’s no big surprise that we have this portfolio of technologies, products with these technologies embedded within them, intended to address engine emissions.”

Whether it’s passenger cars or commercial vehicles, Eaton can provide a complete emissions reduction solution – in the case of passenger cars, the latest additions to the range are intended to support development of both hybrid and pure electric powertrains.

Looking at commercial vehicles, the program of emissions reduction has been focused on diesel internal combustion (IC) and improving existing technologies.

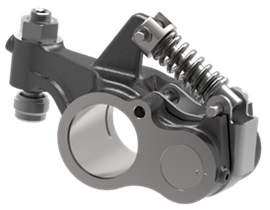

Cylinder deactivation (CDA) unit can also help to reduce engine emissions.

Cylinder deactivation (CDA) unit can also help to reduce engine emissions. (Photo: Eaton)

To break that paradigm, Eaton has recently introduced standalone heating units for emissions aftertreatment systems. The heaters quickly bring the catalyst portion of the system up to temperature (while the engine is still cold), which helps the system more efficiently process and reduce NOx in the exhaust stream.

“This system helps to address the infamous cold start problems with diesel engines, when they emit the highest levels of pollution,” explained Dorobantu. “And it’s really economical, it judiciously uses the vehicle’s electrical system, rather than burning more fuel.”

In the first instance, the system is intended to address new NOx regulations in California, which will require 2024 model year heavy-duty (HD) trucks to achieve a 75% reduction. This will increase to 90% by 2027.

Dorobantu said that development of the catalyst heater started back in 2017, some considerable time before the release of these ultra-low NOx emissions guidelines. “We recognized where society was moving, so we had a good idea of what would be required,” he added.

Valve Actuation

Dorobantu continued by explaining that while Eaton already has a series of technologies intended to address diesel engine CO2 emissions, a next-gen “toolbox” of products is set for imminent launch which will further reduce related GHG emissions.

Mind Uncharted Explore. Discover. Learn.

Mind Uncharted Explore. Discover. Learn.